Global Sourcing and Procurement

VEXOS understands the crucial role that supply chain services play in our customers' businesses. We continuously strive to provide sustainable solutions. VEXOS is uniquely positioned in commodities such as printed circuit boards (PCB) and electro-mechanical components, and can achieve cost reduction for our customers in solutions such as injection molded plastics, metal stampings, sheet metal, extrusions, membrane switches, cable and other products, all of which typically have significant costs involved within electronic assemblies.

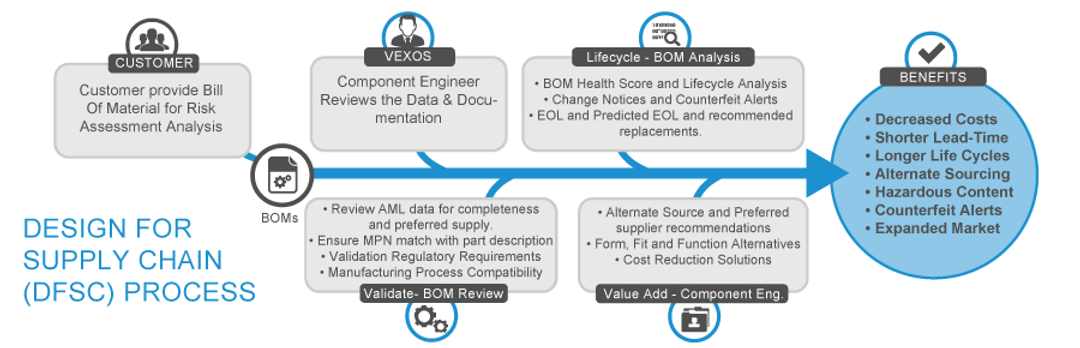

Managing the product through its entire product lifecycle is crucial to our customers' success. By utilizing proprietary analytical tools, VEXOS can provide assistance from inception of a product through field service requirements and manage the lifecycle of critical components on the BOM.

Our sourcing and procurement teams are globally positioned to search out and develop the most cost-effective material supply available. Our global commodity reach allows VEXOS to utilize the best suppliers around the globe, while our regional commodity teams bring value to local customers requiring unique solutions for their regional needs.

Logistics & Aftermarket Services

- Direct end-user fulfillment services

- Kanban program

- Seamless manufacturing transition to/from domestic facility from/to China manufacturing facility

- On-site secure warehouse/depot management

- Kitting, staging and shipping services

- Warranty returns management

- Warranty returns inventory management

- Field returns management

- Hot site spares replenishment programs

- Inventory management services

- Inventory reporting and analysis

- Inventory control management

- Environmental compliance for product disposal and reclamation

- Measurement and management to customer specified metrics

- Customs, tariff and logistics support